Jinan Aotto Technologies Co., Ltd. was established in 2000 and is a wholly-owned subsidiary of Jinan Aotto Automation Co., Ltd. Adhering to the parent company's philosophy of "committed to innovation and pursuing excellence" and its "product leadership" strategy, we focus on Aovita robot intelligent gripping and Aosaff safety protection products, dedicated to serving global automation integrators.

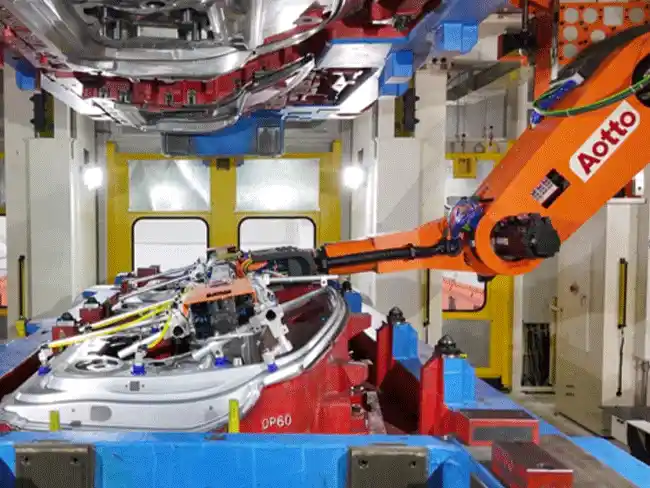

Aovita Series: Robot tool changers, Robot grippers, end of arm tooling, etc.

Aosaff Series: Machine guarding fences, flexible barriers, etc.

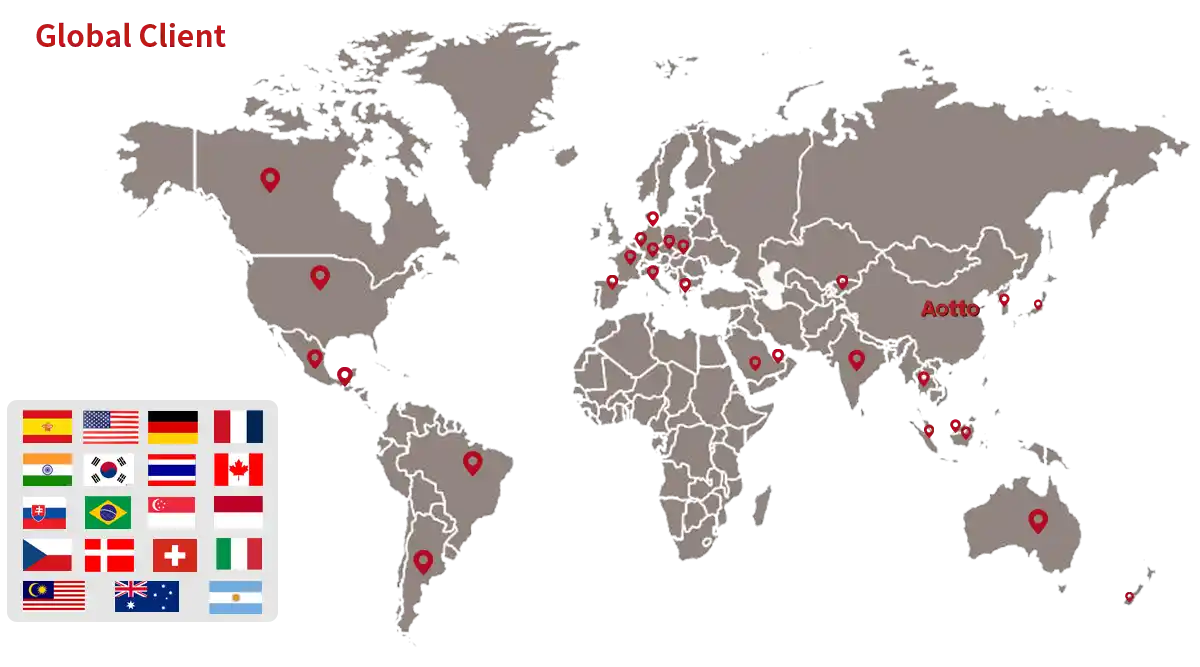

Our products have been exported to the United States, Europe, Southeast Asia, Central Asia, and other countries and regions.

We adhere to the talent concept of "appointing talents to positions of excellence and devoting faith to professionality", create broad development space for employees, enrich employees' lives and stimulate employees' working passion and team spirit by activities, such as collective tourism, interesting sports games, annual meetings and so on. Aotto encourages innovation, guides patiently and systematically, and foster a batch of Aotto’s employees, who are active, progressive, innovative, enthusiastic, open and vigorous.

Mission

Promote industrial upgrading with advanced automation products and services to create value for customers and society.

Vision

To create an Aotto that is proud of its employees, respected by society, and has automation products all over the world.

Core Value

Teamwork, integrity, innovation and excellence.

2000

Established in Jinan, Shandong Province

Primary Business:

-

Overhaul, partial repair, technical renovation, and relocation of stamping equipment

-

Installation and commissioning of stamping automation equipment

2007

1st robotic automation of tandem line

Client: SAIC Lingang base

Partner: COMAU

Stroke: 8.5 SPM

Stamping lines delivered: 200+

2009

Transfer Die Cart

Bundle Turnover

Blank Washer

Blank Oiler

2014

1st Hot stamping line

Client: Dongshi MOTOER ology

Partner: HFM、Schwartz

Stroke:3.5 SPM

Stamping lines delivered:150+

2016

-

Awiz Industry 4.0 : Quality Inspection、Visual Die Protection

-

Aovita Robot Tooling : Robotic tool changer, Gripper, Clamp

-

Aosaff Machine Guarding : Steel Fence、Flexible Barrier

2019

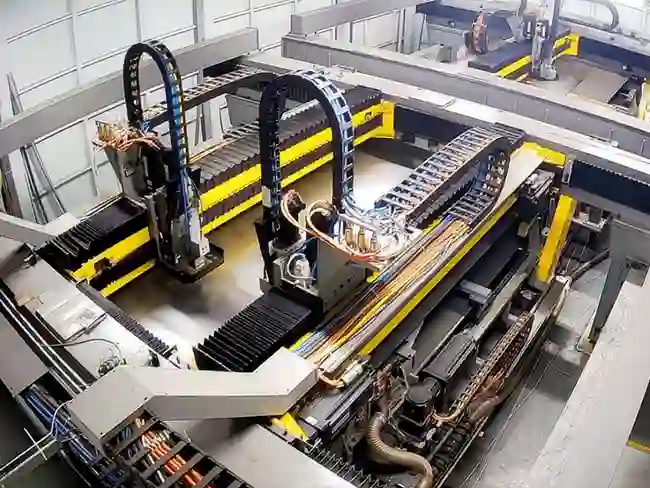

Multi-head Laser Blanking Line

vs Traditional press blanking

-

Laser die-less blanking breaks die limitations, enabling flexible production

-

Supports nesting and simultaneous cutting, with material utilization improved over 10%

vs Toothed plates laser blanking line

-

With the support of the following-up belt, effectively protects the panel from scratches

-

Optional blank washer meets the requirements ofautomotive exterior panel blanking

2022

EOL Automatic Racking Solution

-

On-line visual inspection of stamped parts

-

Automatic Racking

-

AGV

2024

15 SPM High-Speed Stamping Line with Crossbar Feeder Delivered to Automotive OEM

For the past 20+ years' service of the metal forming industry, we have established strategic partnership with many top industry partners, Together, we provide the comprehensive end to end solution with reliable products, industry-leading experience, and consistent reachable service for the long-term successfulness of our customers.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.